BlastCo CNC laser has the capability of cutting various types of metals, stainless steel, mild steel, aluminum, brass, copper ect. in thicknesses ranging from .020 through .6250 in sheets up to 5′ x 10′ (60″ x 120″). If you already have a DXF file you can get an instant quote with our “instant online quote” feature. If not, that’s okay too, send us an email and we will help you put your part into CAD.

Find out how laser metal cutting can help improve the quality of your products or contact us today for a quote.

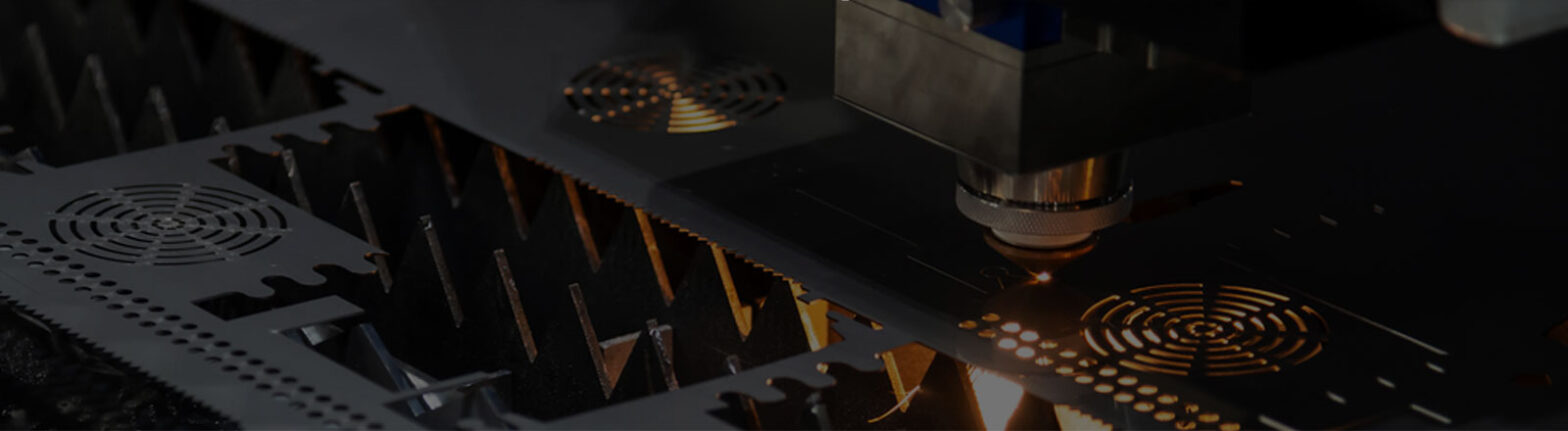

Laser metal cutting uses a high-powered laser beam to cut through metal sheets and plates. It works by focusing a high-powered laser beam on a specific point on the metal’s surface. The laser beam heats and melts the material, forming a narrow and precise line.

Laser metal cutting can be used to cut a wide range of metals at various thicknesses and is more accurate than CNC cutting. At BlastCo Laser, we offer all the metal-cutting laser services you need for commercial and personal use. Contact us today for a quote, or keep reading to learn more.

There are many reasons to choose laser metal cutting for all your metal projects. Laser metal cutting offers a high degree of accuracy, resulting in clean and smooth cuts. It is also an efficient process that can complete complex cuts quickly, reducing production time and cost with minimal waste while reducing the need for secondary finishing.

Three main types of lasers are used in laser metal cutting: CO2, fiber, and Nd: YAG lasers. CO2 lasers are the most commonly used type of laser. They produce a high-powered laser beam and are used for cutting thick and heavy materials.

Fiber lasers use a solid-state crystal to generate the laser beam. They produce a more focused beam that is highly efficient in cutting thin metals and sheet materials.

Like CO2 lasers, Nd: YAG lasers effectively cut thick and reflective materials. They are highly precise and suitable for cutting intricate shapes and patterns.

We can use lasers to cut various types of metals. These include stainless steel, aluminum, brass, copper, titanium, and nickel alloys. The type of laser we can use depends on the thickness of the materials and the type of metal.

Due to its precise nature, laser metal cutting has numerous applications in various industries, including automotive and aerospace, medical, electronics, architecture and construction, jewelry and fashion, and more. We can use laser metal cutting to create complex parts for machinery, etching, and decorative work.

Several factors can affect the laser metal-cutting process. Some of these include material type and thickness, laser power and intensity, cutting speed and feed rate, gas type and pressure, focal point position, the complexity of the design, and more.

Many different services involve laser metal cutting. These services include custom part fabrication, metal cutting, prototyping, design, production runs, and more. Laser cutting is ideal for industries that require tight tolerances to ensure safety and operational efficiency.

Choosing the right laser metal-cutting company is essential, as the cutting service quality can directly impact your production process and the quality of your end product. You will want to consider factors such as experience, equipment, quality control procedures, customization capabilities, turnaround time, quality of customer service, and reputation.

Design is crucial to laser metal cutting as it allows you to produce the most intricate and complex shapes. We can create these designs using computer-aided design (CAD) software for the most accurate results.

Laser metal cutting will continue to grow in importance across all industries as equipment continues to become more accessible. AI and advanced robotics will also play an increasingly significant role in laser metal cutting as well as new alloys and metals.

Do you want to learn more about the laser metal cutting process or request a quote on laser metal cutting? Contact us today to get started.

Please email DXF files to [email protected] for a free estimate